Excavator Base Edges and Blades Content

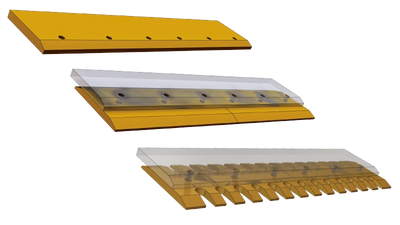

When rebuilding buckets or changing wear edges VBL™ Excavator Base Edges and Blades are the right parts for the job.

VALLITE™ heat treated (thru-hardened) weld-on base edges are available for all OEM* equipment, with or without holes to suit whichever wear parts are required.

Corresponding replacement bolt-on VALLITE™ heat treated (thru-hardened) blades are available with or without a scarifying “sawtooth” edge profile.

Scraper Blades and Router Bits

Opt for VBL™ Scraper Blades and Router Bits in even the toughest conditions.

VALLITE™ heat-treated (thru-hardened) scraper blades and drop center sections are available in a wide variety of sizes to suit all OEM equipment*.

VALLITE™ heat-treated (thru-hardened) router bits and router bit supports are available to suit all OEM equipment*.

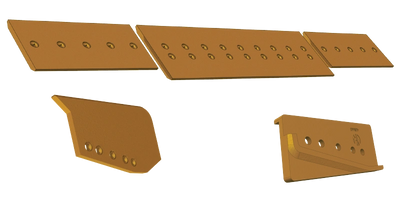

Loader Base Edges and Corners

When it’s time to repair your bucket, choose VBL™ Loader Base Edges and Corners.

VALLITE™ heat-treated (thru-hardened) weld-on base edges are available for all OEM* equipment with or without holes to suit whichever wear parts are required. Corresponding replacement parts such as weld-on bucket corners are also available when a complete re-build is necessary.

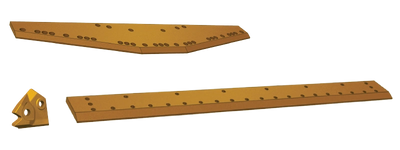

Bulldozer Blades and End Bits

Regardless of your application, VBL™ Bulldozer Blades and Endbits are the best parts for the job.

VALLITE™ heat-treated (thru-hardened) bulldozer blades are available in a wide range of sizes to suit all OEM equipment.*

VALLITE™ heat-treated (thru-hardened) end bits are available in a wide variety of flat, hot cupped and heavy duty versions* for finishing, general duty or severe wear applicatons.

Grader Blades

In even the most demanding grading applications VBL™ Grader Blades are up to the task.

Vallite™ — Hot rolled alloy steel, heat treated and stress relieved for unmatched thru-hardness and impact strength.

High Carbon — Hot rolled steel profile with high carbon content.

Standard grader blades are available in various sizes of flat and curved profiles in single or double bevel*, with hole sizes and patterns to suit all OEM equipment. From the free cutting “sharp” 1/2” X 6” curved to the massive 3” X 16” flat, VBL™ has the right grader blade for any application.

Curved: (1/2” X 6”) to (1” X 8”)

Flat: (5/8” X 6”) to (3” X 16”)

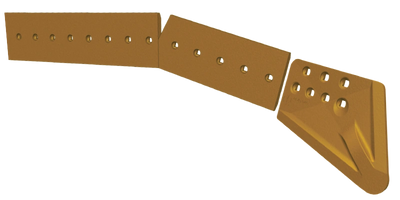

Grader Accessories

When the job needs more than just blades, select from a full line of VBL™ Grader Accessories.

From ripper and scarifier tips and shanks to end bits, overlays and curb runners, VBL™ grader accessories are the perfect complement to VBL™ grader blades.

Grader accessories are available in various sizes and configurations*, with hole sizes and patterns to suit all OEM equipment.

Outlast Winter With PolarFlex™ In Front

Following the Contour of the Road

Plowing closer to the real shape of the road clears more snow. By clearing more snow there are two cost savings. Fewer trips over the same patch of road are required saving time, fuel and blade wear. Less salt is required to melt remaining snow and ice. Reducing salt requirements lowers both the financial and environmental costs associated with snow removal.

Unique Features

- Patented 12″ blade sections that move vertically as well as axially to hug the uneven profile of road surfaces.

- The wearing edge has custom tungsten carbide inserts brazed into the bottom surface. These inserts are of a proprietary chemistry and design, significantly reducing their tendency to prematurely crack and disintegrate.

- The wearing edge is surrounded by a casing of EPDM synthetic rubber pads.

All parts can be recycled.

This is a long form text area designed for your content that you can fill up with as many words as your heart desires. You can write articles, long mission statements, company policies, executive profiles, company awards/distinctions, office locations, shareholder reports, whitepapers, media mentions and other pieces of content that don’t fit into a shorter, more succinct space.

Full Dissassembly

Scrap steel is melted down and turned into new steel. PolarFlex has no rubber bonded to any metal sections, saving thousands of pounds of rubber from the scrap pile and furnace. Used flexible elements from PolarFlex can be easily recycled with other plastics or shipped back to Valley Blades for ecologically responsible disposal. Full disassembly also simplifies system maintenance and repair.

Vibration Reduction

The reduction in vibrations is one of the primary mechanisms responsible for longer blade life. Vibrations damage plow blades, so their reduction directly reduces the wear and tear on blades and prolongs their lifespans. Plows with PolarFlex tend to last significantly longer before repairs or re-welds are required. Vibration reduction also cuts down the noise both inside and outside the plow truck. This creates a more pleasant environment for truck operators and results in more alert, safer operators.

Contact Us

Copyright © 2022 Holland Equipment Co - All Rights Reserved.