Aftermarket Undercarriage Parts

ITR America manufacturers a wide range of Undercarriage Parts - Components for Crawlers, Excavators, Dozers, Compact Track Loaders (CTL), Pavers and more. We have distribution centers full of parts for manufacturers like Caterpillar®, John Deere®, Bobcat®, Hitachi®, Komatsu®, Kubota®, Mitsubishi® and more. ITR America sets the standard for quality within the industry. Manufactured to the highest quality standards, ITR undercarriage parts have earned an excellent reputation in the Mining, Forestry, Construction and Roadbuilding industries for providing long life and trouble free performance. ITR America provides the widest range of undercarriage applications, with coverage for more Makes and Models than other industry suppliers.

Beyond standard undercarriage applications, ITR America also provides specially designed and engineered "Heavy Duty" and "PPR" (Positive Pin Retention) Chains along with Heavy Duty "Purpose Built" track frame components designed for extreme service Forestry and Mining applications. We Pride ourselves on Quality and the results reflect that.

ITR Manufacturers a wide range of Undercarriage Parts & Components including:

- Track Chains (Standard, Heavy Duty & "PPR" Series)

- Forged and Cast Drive Segments

- Drive Sprockets

- Idlers

- Lower Rollers

- Carrier Rollers

- Bogie Assemblies

- Track Tensioning Assemblies and Components

- Heavy Duty Forestry Roller and Idlers

Aftermarket Rubber Tracks

ITR America is a Major Distributor of Rubber Tracks to dealers for thousands of Makes and Models of rubber tracked Excavators, Compact Track Loaders (CTL), Mini and Midi Excavators, Carriers, Pavers and specialty rubber tracked equipment. ITR's Aftermarket Replacement Rubber Tracks are competitively priced and the quality and performance is far superior to other suppliers in the market. Our warehouses are stocked with tracks & undercarriage parts for most manufacturers including John Deere®, ASV®, Bobcat®, Case®, Caterpillar®, Cat®, Ditch Witch®, Gehl®, Hitachi®, IHI®, JCB®, Kobelco®, Kubota®, Mitsubishi®, New Holland®, Takeuchi®, Toro®, Vermeer®, Volvo®, Yanmar® and more.

ITR Rubber Tracks are designed, engineered and manufactured using state-of-the-art technology, high quality materials and craftsmanship providing excellent quality and durability. They are produced to the highest standards based on years of field experience and the results of numerous operational tests in a wide range of working conditions.

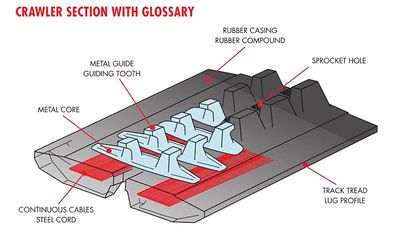

ITR Rubber Track Structure and Main Features

ITR Rubber Tracks use 'Continuous Cable' technology. This market-proven technology provides durability, with flexibility and strength throughout the complete track structure, minimizing premature wear during use. The design integrates various layers of protection into the track providing protection to the cables and to the metal core inserts. A thich outer tread layer of rubber, functions as additional protection to the track structure by absorbing surface wear, impact and abrasion.

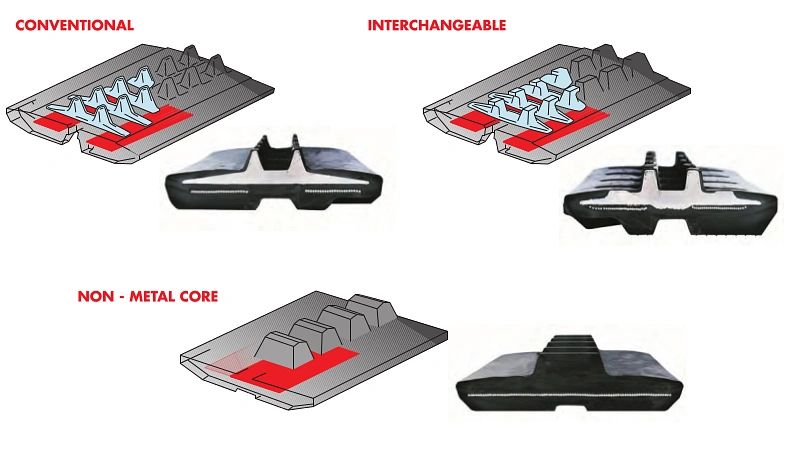

Conventional Style Tracks

Conventional tracks can only be used on undercarriages that have been designed to operate exclusively with rubber tracks. With these Conventional rubber track designs, the rollers do not make contact with the metal track guides except for the purposes of track alignment and protection against de-railing. These types of undercarriages cannot operate with steel tracks.

Interchangeable Style Tracks

Interchangeable rubber tracks can operate on undercarriages designed to utilize both steel and rubber tracks. On interchangeable rubber track designs, the rollers operate in the same manner as a steel track.

Non-Metal Core (NMC) Tracks

The NMC rubber tracks consist of a rubber compound and heavy duty inner cables. The specific lightweight structure, that does not include metal core insert, allows for a more flexible track system while the wide track and the tread pattern provide more traction without losing flotation.

Anti-Vibration (AV) Tracks

AV rubber tracks feature an innovative metal core and track guide designed to reduce vibration and total track weight, offering a longer life and reliability. WithAV rubber track designs, the rollers move along an alternating track roller surface reducing machine vibration.

ITR also stocks and distributes the broadest range of Rollers, Idlers, Drive Sprockets, and Undercarriage Track Frame Components for use on these rubber tracked machines along with Steel Track conversions for use on rubber tracked machines.

- Idlers

- Rollers

- Sprockets

- Compact Track Loaders

- Mini & Midi Excavators

- Paver Applications

- Carrier Applications

- Various Tread Patterns

- Low Surface Disturbance track designs

- Snow Track Applications

- Track Frame Components

- Steel Track conversions for RT machines

Contact Us

Copyright © 2022 Holland Equipment Co - All Rights Reserved.